This article explores common troubleshooting methods and practical solutions for the L4960 . Whether you’re dealing with operational challenges or seeking to enhance performance, this guide provides step-by-step insights for getting the most out of your L4960 system.

Understanding the L4960 and Identifying Common Issues

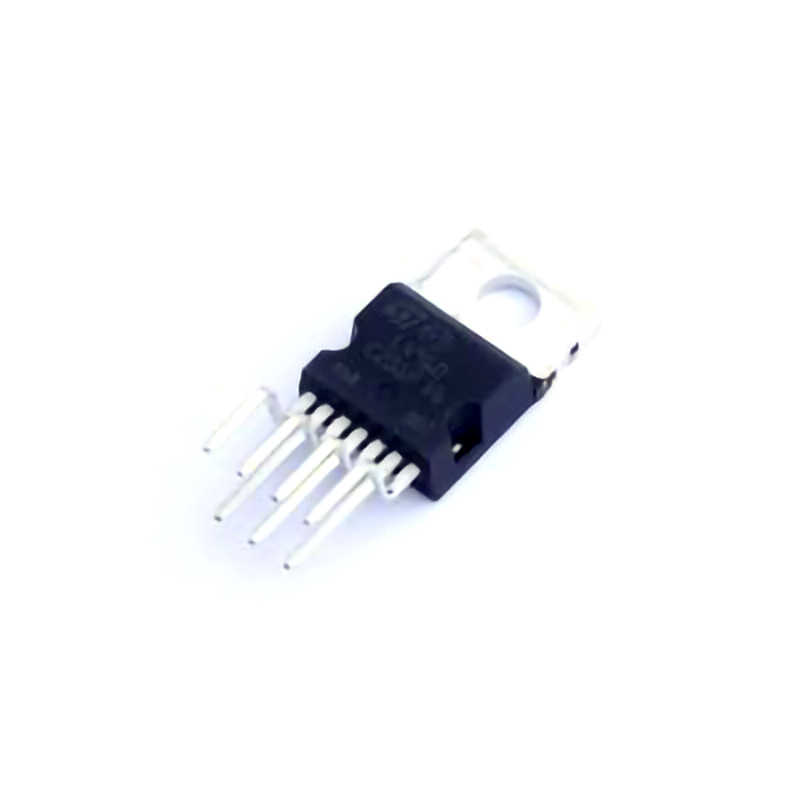

The STMicroelectronics L4960 is a versatile and Power ful integrated circuit designed to streamline the operation of motor control systems, power supplies, and other applications. Although it’s designed to offer robust functionality, like any piece of sophisticated technology, it may experience issues from time to time. Whether you’re an engineer, a technician, or a DIY enthusiast, understanding the common problems associated with the L4960 and how to address them is crucial for maintaining high performance.

Common Issues with the L4960

Overheating and Thermal Shutdown

One of the most frequent issues with the L4960 is overheating, which can cause the system to enter thermal shutdown. The device is equipped with built-in thermal protection, but excessive heat can still lead to system instability or even failure. Typically, this occurs when the system is overloaded or when the cooling mechanism is inadequate.

Solution:

To prevent overheating, ensure that the L4960 is operating within its recommended thermal range. This involves checking the surrounding environment for proper airflow and utilizing heat sinks or fans to help dissipate heat more efficiently. You should also check the load on the system to make sure it is not drawing excessive current.

Power Supply Instability

The L4960 relies on a stable power supply to function correctly. If the voltage supply fluctuates or is not within the required range, the system may experience erratic behavior or fail to operate altogether.

Solution:

Use a regulated power supply with the appropriate voltage and current ratings. Ensure the supply voltage matches the L4960’s requirements (typically between 9V and 40V). A stable, filtered supply can help avoid power disruptions that may cause system instability.

Input and Output Noise

Noise in the input or output signals can significantly affect the L4960’s performance. This can result in miscommunication between the components or unwanted oscillations in the system.

Solution:

Minimize noise by employing decoupling capacitor s on both the input and output sides of the L4960. Proper grounding techniques can also reduce noise interference. Using low-pass filters and shielding components can improve signal clarity and prevent oscillations.

Incorrect Configuration of External Components

The L4960 requires a set of external components to function optimally, including capacitors, resistors, and inductors. Incorrect component selection or poor soldering can lead to malfunctioning systems or degraded performance.

Solution:

Double-check the component values in the L4960’s circuit schematic and verify their ratings. Ensure all components are soldered properly and connected securely. If unsure, consult the datasheet for recommended component specifications and configurations.

Motor Stalling or Irregular Speed Control

When used in motor control applications, the L4960 may face issues such as motor stalling or irregular speed regulation. This is often caused by incorrect PWM (Pulse Width Modulation) signal timing or poor sensor feedback.

Solution:

Ensure that the PWM signal is stable and correctly generated according to the motor specifications. If using sensors for feedback, calibrate them properly. Additionally, check the motor’s load to ensure it is within operational limits and that the L4960’s current control settings are accurate.

Undervoltage Lockout (UVLO) Triggering

The L4960 is equipped with an undervoltage lockout feature to protect the system from operating under insufficient voltage. However, if the supply voltage is near the threshold value, it may trigger frequent lockouts.

Solution:

Check the power supply voltage to ensure it is consistently above the L4960’s undervoltage lockout threshold. If the supply voltage is close to the cutoff value, consider using a more stable power source or adding a voltage regulator to ensure proper voltage levels.

General Maintenance Tips for the L4960

Regular maintenance can prevent many common issues before they become serious problems. Here are some helpful tips to keep your L4960 system running smoothly:

Keep the Circuit Clean: Dust and debris can cause short circuits or impair the performance of the L4960. Periodically clean the circuit board with a soft brush and compressed air.

Monitor System Performance: Regularly check the output of the L4960 to ensure it meets the expected values. This can help you spot issues early and adjust parameters before they cause operational failures.

Use Quality Components: Using high-quality capacitors, resistors, and other components helps avoid many problems such as voltage fluctuations, noise, and overheating.

Advanced Troubleshooting and Solutions for Optimal Performance

While the basic troubleshooting methods outlined above will help resolve most common issues with the L4960, more advanced techniques may be required to address persistent or complex problems. Here are some expert-level strategies and solutions for achieving optimal performance with the L4960.

1. Temperature Management and Thermal Analysis

While overheating is a common issue with the L4960, solving this problem requires a more nuanced understanding of the device’s thermal behavior. If the L4960 is operating near or beyond its maximum temperature limits, it may trigger thermal shutdown, and even intermittent overheating can degrade performance over time.

Solution:

Perform a detailed thermal analysis using an infrared (IR) camera to identify hot spots on the PCB. This can help you pinpoint areas where heat dissipation is insufficient. Consider using more advanced thermal management techniques, such as improving PCB layout for better heat spreading or using more advanced cooling methods like heat pipes or thermoelectric coolers.

2. Power Supply Filtering and Conditioning

Voltage fluctuations can cause erratic behavior in the L4960, especially when the device is operating near its maximum rated voltage. While using a regulated power supply can help, it is essential to pay attention to the quality of the supply itself.

Solution:

Incorporate power conditioning circuits, such as low-dropout regulators (LDOs), to improve power quality. Additionally, using more advanced filtering techniques like multiple stages of capacitors or ferrite beads can further smooth out power supply noise. A detailed analysis of the input power quality can help you identify and mitigate power-related issues.

3. Advanced Signal Filtering for Noise Reduction

If the L4960 is subject to significant input or output noise, this can lead to poor signal fidelity and system instability. Advanced signal filtering is necessary to ensure smooth operation, particularly in sensitive applications such as motor control.

Solution:

Use high-frequency, low-pass filters on both the input and output. The addition of ferrite beads and inductive components in the power supply line can also help suppress noise. Furthermore, PCB trace routing techniques like separating noisy components from sensitive ones and using ground planes can improve signal integrity.

4. Firmware Adjustments for Motor Control

Motor control applications using the L4960 can face issues related to speed regulation, stalling, and load handling. Often, these issues are related to the configuration of PWM signals or feedback systems.

Solution:

Review the firmware controlling the L4960’s motor functions and ensure that the PWM generation is optimized for the specific motor type being used. Fine-tuning the PWM duty cycle, frequency, and modulation settings can significantly improve motor performance. Additionally, use software-based algorithms to optimize speed regulation and prevent stalling under load.

5. Redundancy and Safety Features

In mission-critical applications, the L4960’s failure can lead to significant downtime or system failure. Adding redundancy and enhanced safety features can improve the system’s reliability.

Solution:

Implement watchdog timers or error detection mechanisms to reset or shut down the system if critical parameters are exceeded. Additionally, using dual power supply systems or parallel configurations can improve system resilience by ensuring that a backup power source is available in case of failure.

6. Proactive Monitoring and Diagnostics

In some cases, detecting issues before they escalate is the best approach to maintaining the L4960’s performance. Proactive monitoring can help identify anomalies in real-time, allowing you to take corrective action before a failure occurs.

Solution:

Incorporate real-time monitoring systems that track temperature, voltage, and current levels. Implement diagnostic tools to perform automated system checks and log error codes for future analysis. Early detection allows you to address potential issues quickly and keep the system running smoothly.

By understanding the L4960’s common issues and adopting both basic and advanced troubleshooting strategies, you can significantly enhance its performance, reliability, and longevity. Whether dealing with thermal management, power instability, or complex motor control challenges, these expert tips will help you resolve problems and optimize your system effectively.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.