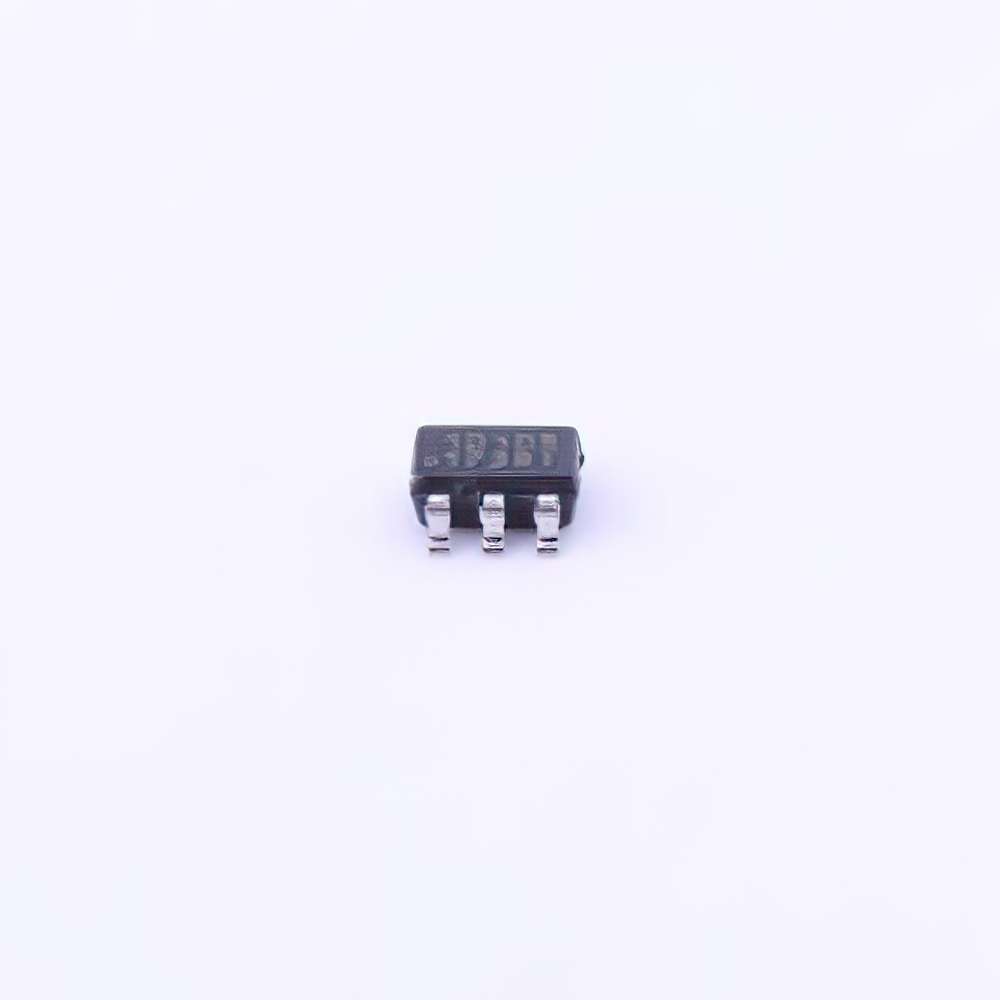

Introduction to AT42QT1010-TSHR Touch Sensor

The AT42QT1010-TSHR is a capacitive touch sensor from Atmel (now part of Microchip Technology), designed to offer an efficient and highly sensitive touch detection solution. It’s widely used in applications where space is limited and ease of use is critical, such as in home appliances, wearables, and automotive systems. The AT42QT1010-TSHR offers great flexibility for embedded systems, combining low Power consumption with high sensitivity to detect touch inputs.

However, like any electronic component, users may sometimes encounter issues with the sensor. Understanding how to troubleshoot and resolve these problems will not only ensure smooth performance but also enhance the longevity and reliability of the system. In this article, we’ll discuss some common problems and their solutions, helping you maintain the integrity of your AT42QT1010-TSHR sensor.

1. Touch Sensor Not Responding

Problem: One of the most common issues users face is when the touch sensor does not respond to touch inputs. This can be frustrating, especially when the device is critical to the operation of a larger system.

Solution:

Check Power Supply: The first step in troubleshooting a non-responsive touch sensor is to verify that the power supply is adequate. Ensure the AT42QT1010-TSHR is powered correctly by checking the voltage levels on the VDD and GND pins. A low or unstable power supply can cause the sensor to malfunction or fail to respond to touch inputs.

Examine Connections: Loose or faulty connections can prevent the sensor from functioning correctly. Inspect the wiring and ensure that all connections are secure and properly connected. Double-check the orientation of the sensor to avoid polarity issues.

Check for Interference: Capacitive touch sensors are sensitive to electrical interference from nearby electronic components or sources of electromagnetic radiation (EMR). Try repositioning the sensor or shielding it from interference, especially in environments with high electromagnetic activity.

Sensor Initialization: Make sure that the sensor is correctly initialized in the software. Check the configuration settings, including threshold values for touch detection, and confirm that they match the environment and application requirements.

2. False Touches or Unstable Response

Problem: False touches or erratic behavior, where the sensor responds to nonexistent inputs, can be another issue. This often results in the sensor triggering actions without actual physical contact.

Solution:

Adjust Sensitivity: The AT42QT1010-TSHR comes with adjustable sensitivity settings, and setting it too high can result in false touches. If the sensitivity is too high, it may react to small environmental changes, such as nearby hand movements or vibrations. Lowering the sensitivity threshold can help minimize these false positives.

Reduce Noise: False touches can also be caused by noise in the signal from surrounding electronic components. Shielding the sensor and reducing the presence of noisy signals from power lines or other circuits will reduce interference. Placing the sensor in a more controlled environment can help prevent unwanted triggers.

Software Debouncing: False triggering can occur when the sensor detects multiple rapid touches due to the mechanical bounce of the sensor’s electrodes. Implementing software debouncing algorithms can help stabilize the response and reduce multiple triggers from a single touch.

3. Inaccurate Touch Location

Problem: When the sensor detects a touch, but the location or accuracy is off, this can lead to user experience issues. For instance, a touch near the edge of the sensor might be recognized at the center, making the device less intuitive to use.

Solution:

Sensor Calibration: Calibration is essential to ensure that the sensor’s touch detection area is accurately mapped. If the sensor is not calibrated correctly, it may misinterpret the location of a touch. You should recalibrate the sensor in its intended operating environment to ensure accuracy.

Improper Placement: The physical placement of the AT42QT1010-TSHR sensor can also affect accuracy. Ensure that the sensor is placed in an environment where it can properly detect touch inputs. The sensor’s electrodes should not be obstructed, and it should be installed on a clean, flat surface for optimal performance.

Check for Obstructions: Any obstructions or materials between the user and the sensor, such as thick glass or plastic, can affect the sensor’s ability to detect touch accurately. Try testing the sensor without such materials to see if the accuracy improves.

4. Inconsistent Sensitivity in Different Areas of the Sensor

Problem: Another issue that users may encounter is inconsistent sensitivity across the surface of the sensor. Certain areas might work perfectly, while others fail to detect touches reliably.

Solution:

Check for Damage: Physical damage to the sensor’s surface can lead to inconsistent performance. Inspect the sensor for any visible signs of wear or cracks that could be affecting the electrodes. If damage is found, consider replacing the sensor.

Environmental Conditions: The sensor’s performance can vary with environmental conditions such as temperature and humidity. Extreme temperatures or high humidity levels may affect the sensor’s sensitivity. If the sensor is being used in such an environment, consider using a more robust version or adding compensation features to handle temperature fluctuations.

Electrode Coverage: In some cases, poor electrode coverage or dirt on the touch surface can result in inconsistent touch detection. Clean the sensor’s surface with a dry cloth to ensure no dust or residues are interfering with the touch detection.

5. Excessive Power Consumption

Problem: Excessive power consumption can be an issue, especially in battery-powered applications where efficiency is paramount. The AT42QT1010-TSHR is designed to be power-efficient, but issues with excessive current draw can arise.

Solution:

Check Power Settings: The AT42QT1010-TSHR has various modes for power saving, including sleep modes. Ensure that these settings are configured properly to avoid unnecessary power consumption. Activating sleep mode when the sensor is not in use can significantly reduce power drain.

Optimize Software: Inefficient software can also lead to excessive power usage. Ensure that the sensor’s polling rate and response time are optimized for your application. Constantly polling the sensor at a high rate can lead to higher power consumption.

Inspect the Power Circuit: Inspect the power circuit for issues such as voltage spikes or excessive current. Adding capacitor s or filtering components can help stabilize the power supply and reduce fluctuations, which can contribute to power inefficiency.

6. Software or Firmware Issues

Problem: Sometimes, the sensor may appear to function incorrectly due to issues with the software or firmware running the sensor. Incorrect or outdated firmware could cause improper touch detection or incorrect behavior.

Solution:

Firmware Update: Ensure that the AT42QT1010-TSHR’s firmware is up to date. Manufacturers often release firmware updates that resolve bugs or enhance performance. Check the manufacturer’s website for the latest firmware version and follow the instructions for updating the sensor’s firmware.

Review Software Implementation: Review the software implementation to ensure it correctly interface s with the sensor. Double-check your initialization code, interrupt handling, and touch event processing. Incorrect software handling can lead to poor sensor performance, so it’s essential to ensure that the code is optimized for the specific application.

Conclusion

Troubleshooting the AT42QT1010-TSHR touch sensor can sometimes seem challenging, but most issues are solvable with careful attention to the hardware and software setup. By following the steps outlined in this article, you can address common problems such as non-responsiveness, false touches, inaccurate touch locations, and more. Whether you’re working with this sensor in consumer electronics or specialized embedded systems, proper troubleshooting will ensure your device operates smoothly and efficiently.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.