Introduction to TPS2553DBVR and Its Functionality in Overcurrent Protection

In the realm of modern electronics, protecting circuits from overcurrent conditions is essential for ensuring device longevity, preventing thermal damage, and maintaining system stability. Overcurrent protection circuits are particularly important in applications where voltage spikes, load changes, or component failures could lead to excessive currents. One of the most effective solutions in managing overcurrent conditions is the use of integrated circuits (ICs) designed specifically for this purpose. Among the various ICs available in the market, the TPS2553DBVR from Texas Instruments stands out as a reliable, efficient, and cost-effective choice for overcurrent protection.

Understanding the TPS2553DBVR

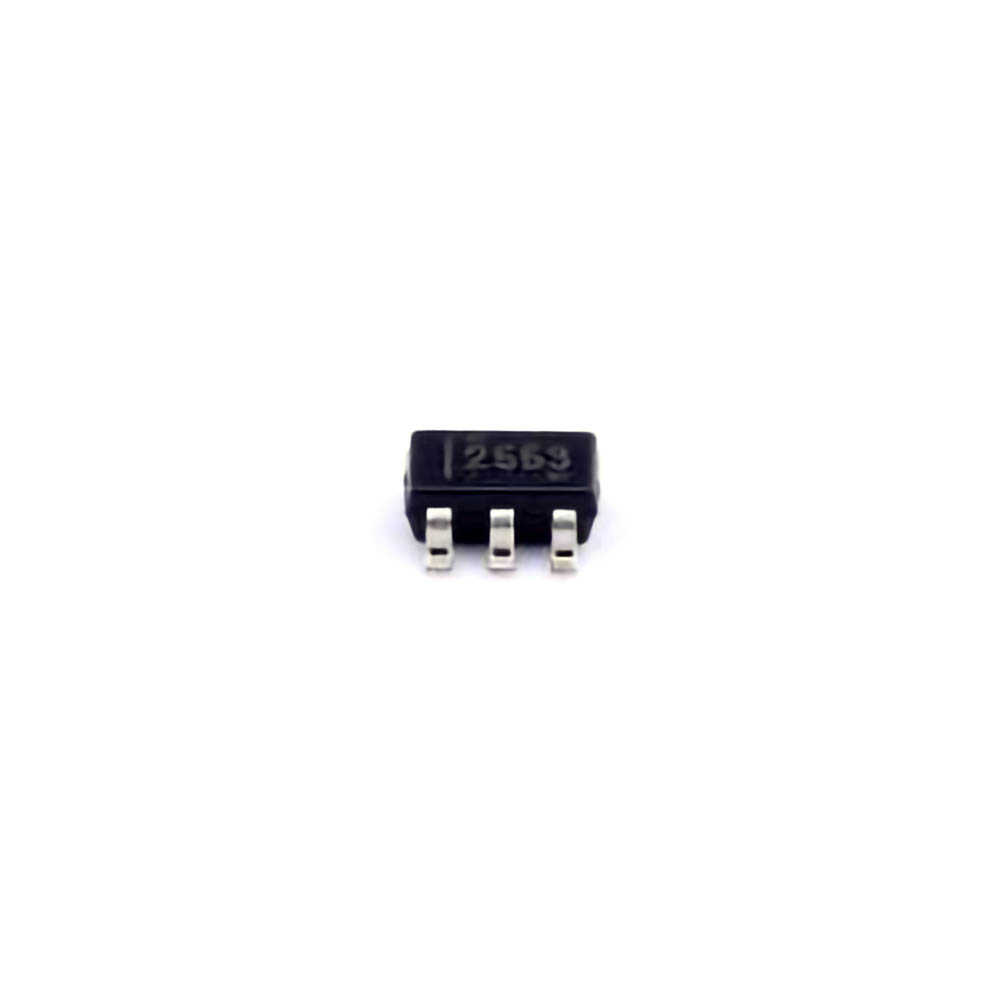

The TPS2553DBVR is a part of the TPS255x family of current-limit and overcurrent protection ICs, and it offers a highly integrated solution for managing current in various applications. This IC is designed to provide adjustable current limiting, fault protection, and thermal shutdown features in a compact, surface-mount package.

The TPS2553 is a high-precision, low-dropout (LDO) current limiter with integrated features that include adjustable current limit, fault protection, and thermal protection. With a maximum current limit of up to 3A, it is ideal for managing Power delivery in systems that require protection against excessive current. The IC is available in a 5-pin SOT-23 package, making it suitable for space-constrained applications, such as portable devices and embedded systems.

Core Features of TPS2553DBVR

Some key features of the TPS2553DBVR that make it a great choice for overcurrent protection include:

Adjustable Current Limit: The device allows for precise control over the current limit threshold, making it adaptable to a wide variety of power management requirements.

Thermal Shutdown: In addition to overcurrent protection, the TPS2553DBVR includes an integrated thermal shutdown feature, which helps to prevent the IC and surrounding components from damage due to excessive heat.

Fault Protection with Automatic Recovery: The TPS2553DBVR includes fault detection circuitry that monitors overcurrent and thermal conditions. If a fault occurs, the device enters a safe state and automatically recovers once the fault condition is removed.

Low Quiescent Current: The IC has a low quiescent current, making it ideal for battery-powered applications where power consumption is a major concern.

Small Form Factor: The SOT-23 package offers a compact solution, which is critical for designs with tight space constraints.

High Precision: With an adjustable current limit that can be set through external resistors, the TPS2553DBVR ensures high accuracy in protecting circuits from overcurrent.

How TPS2553DBVR Works

The TPS2553DBVR operates by monitoring the current flowing through the load and limiting it to a preset threshold. If the current exceeds the set limit, the IC limits the current to protect the circuit and prevent damage to the components. It does so by adjusting its internal circuitry to reduce the output voltage, which in turn limits the current. The device also includes a fault flag that can be used to notify the system when a fault occurs, allowing for further diagnostic or corrective action.

The adjustable current limit is set using external resistors, allowing designers to fine-tune the protection level for specific applications. Additionally, the thermal shutdown feature ensures that the IC will protect itself and other components from overheating by shutting down when temperatures reach critical levels.

Real-World Applications and Case Studies of TPS2553DBVR in Overcurrent Protection

The versatility and reliability of the TPS2553DBVR make it suitable for a wide range of applications across various industries, including consumer electronics, automotive, and industrial systems. Let’s explore some real-world case studies and applications where this integrated circuit has proven its worth.

Application 1: Overcurrent Protection in USB Power Delivery Systems

One of the most common applications of the TPS2553DBVR is in USB power delivery systems, where it provides overcurrent protection for devices such as smartphones, tablets, and laptops. USB power delivery is a technology that allows devices to charge at higher power levels, up to 100W in some cases. However, with higher power comes the risk of overcurrent conditions that could damage the device or power source.

In a typical USB power delivery application, the TPS2553DBVR is used to limit the current supplied to the connected device. If the device draws more current than the set threshold, the IC will restrict the current to prevent damage. This is especially important in power banks or charging hubs that may power multiple devices simultaneously, where overcurrent conditions are more likely due to varying load requirements. The adjustable current limit feature ensures that the system can accommodate different power profiles, making the TPS2553DBVR a perfect fit for such applications.

Case Study:

A USB charger manufacturer incorporated the TPS2553DBVR in their power delivery circuit to ensure that their chargers would not overheat or become damaged during high-power charging events. With the adjustable current limit, the charger could safely charge devices such as tablets or laptops, while the thermal shutdown feature prevented the charger from overheating under prolonged high-power operation. This system proved to be highly reliable, and the thermal protection ensured that the charger operated safely even in less-than-ideal conditions.

Application 2: Automotive Overcurrent Protection

The automotive industry is increasingly relying on sophisticated electrical systems that support everything from infotainment to autonomous driving features. As vehicles incorporate more electronics, ensuring the protection of sensitive components from overcurrent conditions becomes increasingly crucial.

In automotive applications, the TPS2553DBVR is used to protect circuits that handle critical systems like battery management, power distribution, and communication interface s. For example, the IC might be deployed in the power supply to a telematics control unit (TCU) or in a power distribution network for infotainment systems. By using the TPS2553DBVR, designers can ensure that any unexpected surge in current will trigger the protection mechanisms of the IC, preventing damage to the TCU or other components.

Case Study:

A Tier 1 automotive supplier used the TPS2553DBVR in a power distribution unit for an electric vehicle (EV). The goal was to ensure that the unit would protect the vehicle’s sensitive electronics, such as the battery management system (BMS) and the infotainment system, from short circuits or sudden power surges. The adjustable current limit feature allowed the company to tailor the protection to the specific requirements of each component, while the thermal shutdown ensured that the power distribution unit would not overheat during high-load conditions. The result was a more reliable and robust system that significantly reduced the risk of system failure due to overcurrent conditions.

Application 3: Industrial Equipment Overcurrent Protection

In industrial environments, electronic equipment such as motor Controllers , PLCs (Programmable Logic Controllers ), and power supplies are often subject to fluctuating power demands and harsh conditions. Overcurrent protection is vital to ensure the safety and longevity of such equipment.

The TPS2553DBVR provides an ideal solution for industrial systems where power surges or faults can occur due to factors like motor startup, load changes, or faulty wiring. In these systems, the IC can be used to limit the current going to critical components, such as sensors, actuators, or industrial computers.

Case Study:

A manufacturer of industrial automation systems integrated the TPS2553DBVR into their PLC system to protect the logic control circuitry and communication buses. The current-limiting feature ensured that the PLC could operate safely even if there were short circuits in the connected peripherals. By preventing excessive currents, the system reduced the risk of costly downtime or repairs due to component failure. The thermal shutdown feature also provided an added layer of protection, ensuring that even if there was an overheating event, the system would automatically recover without requiring manual intervention.

Conclusion: The Future of Overcurrent Protection with TPS2553DBVR

The TPS2553DBVR’s combination of adjustable current limiting, thermal protection, and automatic recovery makes it an indispensable tool in modern circuit protection. Its versatility across industries such as consumer electronics, automotive, and industrial systems highlights its importance in ensuring the safety and reliability of electronic designs.

As electronic devices continue to become more complex and power-hungry, integrated solutions like the TPS2553DBVR will play an even more critical role in preventing overcurrent damage. The growing trend of power-hungry devices, high-power USB charging, and automotive electrification will only increase the demand for reliable current-limiting ICs, and the TPS2553DBVR is well-positioned to meet this demand.

By providing a comprehensive, easy-to-integrate solution for overcurrent protection, the TPS2553DBVR helps designers build safer, more durable systems. As technology evolves, we can expect even more advanced features and improvements in ICs like the TPS2553DBVR, further enhancing their effectiveness in managing overcurrent conditions and protecting sensitive electronic systems.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.