Introduction to the ADS1110A0IDBVR and Common Issues

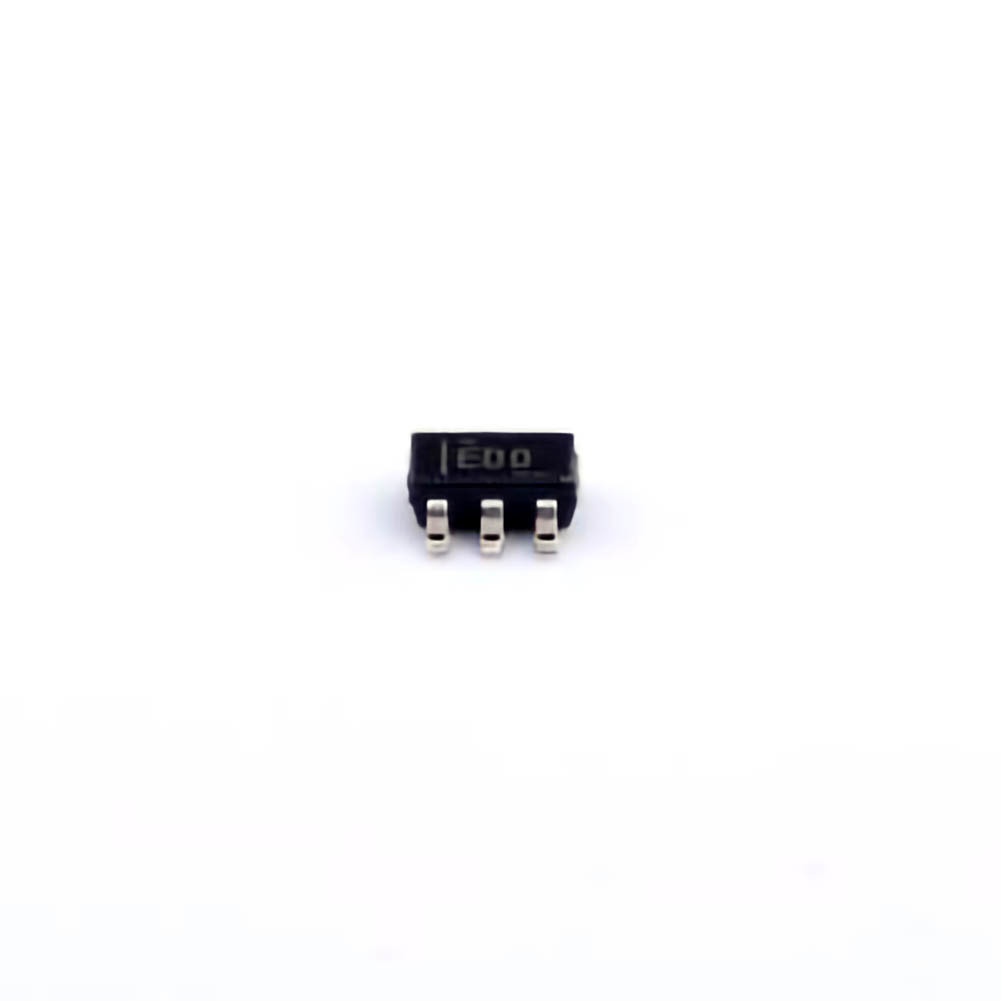

The ADS1110A0IDBVR is a high-precision, 16-bit analog-to-digital converter (ADC) from Texas Instruments, designed for applications requiring accurate and low- Power measurements. It features a built-in programmable gain amplifier (PGA) and operates in a low-voltage environment, making it an excellent choice for battery-powered and portable devices, industrial instrumentation, and sensor systems.

While the ADS1110A0IDBVR is a reliable and effective component, like any piece of electronics, it can face operational challenges. These challenges may arise from a variety of factors, including improper setup, interference, or issues with the surrounding circuit components. Understanding the common issues you may encounter, as well as practical troubleshooting methods, can significantly improve your experience with the device.

1. Power Supply Issues

One of the most frequent causes of malfunction in electronic systems is power-related problems. The ADS1110A0IDBVR requires a stable power supply within a specified range (2.0V to 5.5V). If the voltage supplied to the device falls outside this range, it may not operate correctly or could fail to turn on altogether. Inadequate or fluctuating power can lead to inaccurate measurements or cause the ADC to reset unexpectedly.

Solution: Ensure that your power supply provides a stable voltage within the required range. If you’re using a battery-powered setup, ensure that the battery is not running low or delivering inconsistent voltage. Additionally, consider using a low-dropout regulator (LDO) or a more stable power source to ensure the ADS1110A0IDBVR receives the correct voltage.

2. Incorrect Gain Setting

The ADS1110A0IDBVR features a programmable gain amplifier (PGA) that allows you to adjust the input signal range for more precise measurements. However, selecting the wrong gain setting can lead to clipping or poor resolution. If the input signal is too large for the chosen gain, it may cause the ADC’s output to saturate, resulting in a loss of useful data.

Solution: Before selecting a gain, it’s essential to understand the characteristics of the input signal. Use the PGA settings to scale the input voltage properly, ensuring that the signal stays within the ADC's input range. If necessary, experiment with different gain settings to find the optimal configuration for your application.

3. Noise and Interference

Noise and electromagnetic interference ( EMI ) are common challenges in precision measurement systems. The ADS1110A0IDBVR can be particularly sensitive to noise, especially in high-precision applications. Noise can come from various sources, including nearby power lines, switching devices, and even the analog signal source itself. This interference can cause fluctuating readings, reducing the accuracy of your measurements.

Solution: To minimize noise interference, follow best practices for analog circuit design, such as grounding the system properly, using decoupling capacitor s near the power supply pins, and shielding the ADC from electromagnetic interference. Additionally, ensure the analog input signal is properly conditioned, using filters to reduce high-frequency noise.

4. I2C Communication Issues

The ADS1110A0IDBVR communicates with external devices using the I2C protocol, which is a relatively simple but sometimes problematic method for data transfer. Common issues with I2C communication include improper addressing, clock stretching problems, or noisy signals on the SDA (data) and SCL (clock) lines. These communication issues can lead to unreliable data transmission, incorrect readings, or system failure.

Solution: Verify the I2C connections carefully, ensuring that the clock and data lines are correctly wired. Use pull-up resistors on both the SDA and SCL lines to ensure proper communication. Additionally, ensure that the device address is correctly configured in your software to avoid address conflicts. If you’re using a longer I2C bus, consider reducing the clock speed to improve reliability.

5. Faulty Analog Input

The ADS1110A0IDBVR’s performance is heavily dependent on the quality of the analog input signal. If the analog input is noisy, fluctuating, or improperly grounded, it can cause incorrect readings or errors in the conversion process. Additionally, applying voltages outside the specified input range of the ADC can damage the device.

Solution: Always ensure that the input signal is within the voltage range specified in the datasheet. Properly condition the signal before it reaches the ADC, using op-amps, filters, or voltage dividers as necessary. If you are working with differential inputs, ensure that the differential voltage remains within the device’s limits.

Advanced Troubleshooting Tips and Solutions

While the issues discussed above are some of the most common, there are several other potential problems that users of the ADS1110A0IDBVR might encounter. Let’s dive into some advanced troubleshooting strategies and solutions to help you resolve more complex issues.

6. Conversion Time Delays

The ADS1110A0IDBVR includes an onboard sample-and-hold capacitor, which allows for precise analog-to-digital conversion. However, if you notice delays or unexpected latency in the conversion process, the issue may lie with the configuration of the conversion time. The ADS1110A0IDBVR offers several different output data rates, and improper settings may cause conversion delays or slower performance than expected.

Solution: Review the datasheet and check the selected output data rate. The ADS1110A0IDBVR offers multiple sampling rates (from 8SPS to 860SPS), so adjust the data rate based on your application’s needs. Higher sampling rates typically lead to faster conversions, but they may also consume more power and increase noise. Select an optimal rate based on your trade-offs between speed and accuracy.

7. Saturation or Clipping of the ADC Output

Saturation or clipping occurs when the input signal exceeds the ADC’s maximum input range, causing the converter to output its maximum or minimum value. This is a common issue when dealing with sensors that produce signals with a larger range than what the ADC can handle.

Solution: You can address this problem by carefully adjusting the gain settings on the ADS1110A0IDBVR’s PGA. Ensure the PGA is configured to scale the input signal properly to prevent saturation. Additionally, monitor the input signal and make sure that it does not exceed the ADC’s reference voltage (Vref) or its input limits. In cases where the signal exceeds the ADC’s capabilities, consider using external attenuation or gain circuits.

8. Temperature Sensitivity

The ADS1110A0IDBVR, like all electronic components, is sensitive to temperature variations. Significant temperature changes can affect the ADC’s accuracy, causing drift in the output. This is particularly important in precision applications where temperature stability is critical.

Solution: To mitigate temperature-induced errors, consider using external temperature sensors to monitor the system’s temperature. If necessary, apply calibration techniques to account for temperature drift. Additionally, ensure that the ADC operates within its specified temperature range and that proper thermal management techniques are applied to the system.

9. Software and Calibration Issues

Software-related issues, such as incorrect configuration or poor calibration, can also lead to incorrect readings. Calibration is critical for maintaining the accuracy of the ADS1110A0IDBVR, especially when it’s used in systems that require high-precision measurements.

Solution: Double-check the software initialization and configuration steps. Ensure that the ADC is being initialized with the correct settings (such as the correct sampling rate, PGA gain, and reference voltage). If you’re working in an environment where calibration is important, perform a regular calibration process using known reference voltages or signals. Also, take advantage of the built-in self-calibration features offered by some ADS1110A0IDBVR configurations to improve measurement accuracy.

10. Hardware Layout and Grounding Problems

Poor PCB layout and grounding practices can exacerbate many of the issues discussed above, especially when it comes to noise and signal integrity. Issues like high-frequency interference, ground loops, or insufficient decoupling capacitors can undermine the performance of the ADS1110A0IDBVR.

Solution: Follow proper PCB design guidelines to ensure a clean, low-noise layout. Minimize the length of the analog input traces and ensure that the power and ground planes are properly designed to reduce noise coupling. Use decoupling capacitors close to the power supply pins of the ADS1110A0IDBVR to reduce voltage spikes and noise. Also, ensure that the analog and digital grounds are separated and join at a single point to avoid ground loops.

Conclusion:

By addressing the common issues and applying the appropriate troubleshooting techniques discussed in this guide, you can enhance the performance and reliability of your ADS1110A0IDBVR-based systems. Whether you're dealing with power supply issues, communication problems, or signal integrity concerns, having a solid understanding of the potential challenges and their solutions will help you maintain accurate, efficient, and reliable ADC performance in your designs. Happy troubleshooting!

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.